#threaded rod screw

Explore tagged Tumblr posts

Video

youtube

FIXDEX & GOODFIX technical department explains new energy technology

#youtube#Wedge anchor bolts#threaded rods#din975#self drilling screws#chemical anchor#drop in anchor#foundation bolt#hex nut#flat washer#hex bolt#Photovoltaic Bracket#angle brackets#Stainless steel bracket#Bracket Clamp

3 notes

·

View notes

Text

Jinnox Bolt is one of the leading Bolts, Nuts, Washers, Threaded Rod, Screw & Coated Fasteners Manufacturers in India. Our broad product line uses only the highest quality materials to ensure that it meets and exceeds industry requirements. We are very proud of our experienced team of experts who are committed to providing amazing customer service by ensuring that every product we manufacture is of the highest quality and delivered on time.

Bolts: https://jinnoxbolt.com/bolt-manufacturer-supplier-stockist-india/

Nuts: https://jinnoxbolt.com/nut-manufacturer-supplier-stockist-india/

Washers: https://jinnoxbolt.com/washers-manufacturer-supplier-stockist-india/

Threaded Rod:https://jinnoxbolt.com/threaded-rods-manufacturer-supplier-stockist-india/

0 notes

Text

Nuts | Screws | Threaded Rods | Fasteners - Caliber Enterprises

Caliber Enterprise is a well-known Nuts Manufacturers in India. Our firm also supplies Screws, Threaded Rods, Fasteners and so on.

For More Details:

Website: https://www.caliberfasteners.com/

Nuts: https://www.caliberfasteners.com/manufacturer/nuts/

Screws: https://www.caliberfasteners.com/manufacturer/screws/

Threaded Rods: https://www.caliberfasteners.com/manufacturer/threaded-rods/

Fasteners: https://www.caliberfasteners.com/fasteners-manufacturer-supplier-india.php

0 notes

Text

Anand Steel: What Are the Benefits of Using Nuts?

Nuts are critical components in the global of hardware and creation. They are available in numerous sizes and styles and are used at the side of bolts and screws to lock materials together securely. In this blog, we are able to delve into the benefits of using nuts, the different sorts to be had, and how they make a contribution to the stableness and durability of numerous systems. We can also touch on associated hardware collectively with washers, socket screws, self-tapping screws, and threaded rods, to offer a whole knowledge of their significance.

1. Strength and Stability

Secure Fastening

Nuts are designed to offer a secure fastening when used with bolts and screws. This mixture creates a sturdy and sturdy connection that could resist widespread strain and pressure. The use of nuts ensures that the set up substances live intact and aligned, it truly is critical for structural integrity.

Load Distribution

When used with washers, nuts assist distribute the burden flippantly throughout the floor of the cloth. Washers act as a buffer among the nut and the material, stopping damage and ensuring that the pressure is calmly spread. This load distribution is critical in preventing material fatigue and failure, specially in high-stress programs.

2. Versatility and Adaptability

Various Applications

Nuts are utilized in a large kind of packages, from easy household upkeep to complex business gadgets. Their versatility makes them a necessary issue in plenty of industries, which includes manufacturing, car, aerospace, and production.

Compatibility with Different Fasteners

Nuts are like minded with various fasteners, together with bolts, screws, and threaded rods. This compatibility lets in for bendy and adaptable fastening answers, accommodating specific sizes and varieties of hardware. For example, a socket screw, that is a sort of screw with a hexagonal socket in its head, may be paired with a nut to create a strong connection in limited spaces.

3. Ease of Use and Installation

Simple to Install

Nuts are pretty simple to install and do not require specialized devices. A simple wrench or socket set is commonly sufficient to tighten or loosen them. This ease of setup makes nuts a realistic desire for each expert and DIY programs.

Reusable

Unlike a few fasteners that could best be used as soon as, nuts can often be reused more than one times. This reusability makes them a fee-powerful alternative for various projects, as they'll be removed and reapplied without dropping their effectiveness.

4. Durability and Longevity

Material Choices

Nuts are available in numerous substances, including chrome steel, brass, aluminum, and nylon. Stainless metal nuts, for example, are fantastically immune to corrosion and rust, making them ideal for outdoor and marine packages. This durability ensures that the fixed structures stay steady and intact for extended periods.

Corrosion Resistance

Many nuts are designed to withstand corrosion, which is in particular vital in harsh environments. Using nuts made from corrosion-resistant materials ensures that the fasteners do not degrade over time, retaining the integrity of the relationship.

5. Specific Types of Nuts and Their Benefits

Hex Nuts

Hex nuts are the most common shape of nut and are characterised with the resource in their hexagonal form. They are utilized in a big range of applications and offer excellent grip and torque.

Lock Nuts

Lock nuts are designed to resist loosening because of vibration or torque. They are typically applied in device and vehicle programs in which keeping a steady connection is crucial.

Wing Nuts

Wing nuts have sticking out "wings" that allow for smooth hand-tightening. They are regularly utilized in applications where the nut needs to be often adjusted or eliminated, together with in furnishings meeting.

Flange Nuts

Flange nuts have an included washing machine that enables distributing the load and gives a greater strong fastening. They are normally utilized in vehicle and structural applications.

6. The Role of Anand Steel in Providing Quality Hardware Solutions

Anand Steel, a firm of excellent hardware, offers an in-depth kind of nuts, washers, socket screws, self-tapping screws, and threaded rods. Their dedication to high-quality and client delight ensures that you get dependable and strong fasteners to your duties. By deciding on Anand Steel, you can be confident that your fastening goals can be met with precision and excellence.

7. Complementary Fasteners: Washers, Screws, and Rods

Washers

Washers are used along facet nuts and bolts to distribute the load and save you damage to the cloth. They are to be had severa types, including flat washers, spring washers, and lock washers, every serving a specific reason.

Socket Screws

Socket screws, additionally called Allen screws, have a hexagonal socket in the head that permits for a stable and unique fastening. They are normally utilized in programs wherein a flush end is needed.

Self-Tapping Screws

Self-tapping screws are designed to create their personal threads as they'll be driven into the cloth. They are perfect to be used in materials like steel and plastic, in which pre-drilling is not viable or sensible.

Threaded Rods

Threaded rods are lengthy rods with non-stop threading alongside their duration. They are applied in applications wherein a long, stable connection is wanted, collectively within production and device.

8. Conclusion

Nuts play a crucial function in providing stable, sturdy, and sturdy connections in numerous packages. Their versatility, ease of use, and compatibility with other fasteners motive them to an important trouble within the hardware industry. By experiencing the benefits and styles of nuts, as well as their complementary fasteners, you could make informed picks for your initiatives.

Anand Steel gives a large style of excellent nuts and special hardware solutions, ensuring that your fastening dreams are met with reliability and precision. Whether you are an expert contractor or a DIY enthusiast, Anand Steel's products will assist you obtain solid and long-lasting consequences.

0 notes

Video

youtube

Mop rod threading machine broom handle screw machine wood broom handle making machine

0 notes

Note

9, 38, 42, 88 :)

9. “if you stop, i’ll stop”

38. “you make me so wet”

42. “please don’t think i’m weird for this”

88. “that looks too big”

🥰💜

"That looks too big..."

Vidal whispered as she grabbed Agnes' bicep a little harder, trying to stifle a laugh. Agnes whistled in response, in agreement. She picked up the box hanging from the shelf and checked the measurements of the silicone toy. She shot a sideways glance at Vidal, making a screwed up face that made Vidal laugh out loud.

"Yeah...you're right...I mean, unless you're into it...please don't think I'm weird for this but, if you think you can handle it...we can get it; try it out?"

Agnes kept her voice down, as if the cashier hadn't heard it all already. The Agent and the Detective found themselves on a Friday night at one of Eastview's stag shops. It was actually Agnes' idea; something that surprised Vidal. The detective was coming out of her shell a little more, taking baby steps towards being more comfortable, more open. She drove them over to Eastview with the location set in mind. Holding Vidal's hand, the two of them entered the store.

Now, they were down another aisle, giggling like two school girls. Maybe it was the drinks they had at dinner before coming here or, the quick yet messy make out session in the car. Vidal was basically sitting in Agnes lap in the drivers seat; her hand pushed down into Agnes' pants. She had come twice onto Vidal's fingers; the thrill of possibly being caught turned her on. And now, they were laughing over the various sizes of the silicone toys all around them.

Vidal suddenly snatched the box out of Agnes' hand, shooting her partner a quick smile as she took off down the aisle, making Agnes chase her down. She reached the checkout before Agnes could even round the corner; credit card out before Agnes could even be in arms length of Vidal. By the time she got there, the cashier was handing Vidal the receipt and wishing her a 'good night'. Vidal flashed Agnes another sneaky smile, good night was right, she thought.

Agnes held onto the sleeve cuff of Vidal's jacket, following the agent out of the store with her new prized possession. She didn't even get a word in before they reached the car; Vidal digging into the bag and pulling the box out.

"I didn't think you were actually going to get it..."

Agnes announced as she unlocked the car doors for them, opening Vidal's to let her in. She wasn't even paying attention, too busy trying to rip the box open. She had one leg in the car, half squatted as she used her fingertips to peel away the cardboard. Agnes watched her curiously, a half smile on her face.

"Vidal? Hello? What the fuck are you doing? Do you really need to look at it right now?"

Vidal ignored her, finally getting into her seat and closing the door shut behind her. Agnes shook her head, walked over to the drivers side and got in.

"Vidal, what the fuck-"

And her eyes drifted down to Vidal's lap and realized why she was so anxious to get the box open. She had pulled her pants down just far enough for Agnes to see that she had been wearing her harness this entire time with no toy set inside. She threaded the new, much bigger toy through the ring and smiled to herself in pride. Agnes stifled back a moan; her body finally catching up with her mind.

"Good thing there's only parking in the back here, huh? You wanna do me a favor, Daddy? You wanna suck Mommy's cock?"

Agnes felt like there was a rod of hot metal pushed through her chest at Vidal's words. This time, she did let out her moan. She could never understand how Vidal made everything sound so fucking dirty yet innocent when she used that bratty little voice of hers. It drove Agnes wild and she knew that Vidal knew it too. Knew that when she used this tone, Agnes was going to fold, and fold, she did.

Agnes moved herself around, got herself as comfortable as she could to lean herself over towards Vidal's lap. Her mouth made contact with the tip of the toy and realized, in that second, just what she had gotten herself into. It was much bigger than what they were using, what they were used to. She hesitated just for a second, realizing then that Vidal flipped the tables on her. Again. She was going to be the one to see if she could "handle" the toy; not Vidal. Agnes moaned again at the thought, knowing Vidal was smiling above her.

"If you stop, I stop. Ok, Baby?"

Agnes didn't nod or shake her head. What the hell was Vidal talking about? She kept her lips around the head of the toy, sucking slightly, unsure of what was to come.

Agnes felt Vidal's hand come down, grabbing Agnes'. She allowed the agent to do whatever it was she was planning; her arm and hand going limp for her to control. Vidal brought Agnes' hand just below the harness, just below the base of the toy. Her fingers felt what Vidal brought them too and another moan left her, onto the silicone in her mouth.

She was wearing fucking crotch-less underwear and she didn't even know, hadn't even realized it; even though they fucked around earlier already. Agnes chalked it up to her habit of just pushing Vidal's underwear to the side; familiarity making her accustomed to what she was used to.

Agnes knew what she had to do in that moment. Vidal was asking for both her mouth and fingers and like the good girl she was, Agnes complied. Her mouth was working Vidal's cock, fingers working inside and out of her pussy. The agent pushed her head back into the headrest, closing her eyes and allowing herself to feel everything she had started.

"You make me so wet...I'm sure you can feel it...all over your fingers..."

Vidal was breathing heavily, her words coming out in long, low strands. If you stop, I stop rang through Agnes' head and in that moment she realized she wouldn't dare. Not now, especially when she felt the agents hand come down and grab hold of the base of her ponytail, keeping her situated between her legs twofold.

#Moral of the story is do not let these two out in public thanks!#Ask#Ask game#Marvel#Agatha All Along#Butch!Agatha#Agnes O'Connor#Agnes of Westview#Detective Agnes O'Connor#Agent Vidal#Writing#Writing prompts

19 notes

·

View notes

Text

I picked up a moderately sized capsule vending machine for 25 bucks and I figured out how to get out of spending double that importing new keys / locks from the US.

The locks on these things just screw onto a 1/4" threaded rod. The locking mechanism stops it from turning & the key gives you a grip to hold on to. I don't need it to lock, so I just made a thing that screws onto the rod out of stuff from the hardware store for maybe 4 bucks.

The wingnut makes it easy to unscrew by hand, and the washers make it fill out the slot for the lock. This is necessary because the 2 locks are also necessary structural components of the device- one bolts the front panel closed and the other bolts the top and bottom together through a long rod.

Very excited about my low cost project. No idea what I'm going to put in it.

#it was probably cheap because it only takes US quarters#not only that but what even can you get for 50c nowadays#the cheapest options for locks i found were $25CAD a pop after S&H#also a couple us websites that straight up stopped shipping here.... rip

15 notes

·

View notes

Text

really annoying thing i notice online is that when i look up how to do something pertaining to a specific hobby, sometimes the help threads online will be full of people being like "dont fuck with it, take it to a professional"

in this context, im talking about guitar. more specifically, the string height on one of my guitars was a little too high, and the normal methods of adjusting it weren't working, so i looked up how to do a truss rod adjustment.

the thread that i found was 80% people being like "if you don't know, take it to a professional," but thankfully there were a few others in there that outlined the answer i was looking for and it was incredibly simple.

the thing everyone was telling the op to "take it to a pro" for was as simple as rotating a screw the right way. left releases string tension, right increases it. i rotated that screw by a quarter rotation, and wow! that was it! it was fixed!

like, yeah, i get it. making that adjustment can fuck up your guitar if you don't do it right, but who tf do these people think i am? do you really think me, a guitar player, can afford to take my shit to a pro any time i need something adjusted? do you think they'll just do it for free?? cuz they fucking won't.

they'll take my guitar, hold onto it for a bit while they work through a backlog of other guitars they need to work on, then finally give it back to me after 5 weeks and charge me $100 for something that took me less than fifteen minutes to do on my own.

23 notes

·

View notes

Text

so you may recall that we have a number of spinning wheels, because of who we are as people and also because i love them. and we decided after buying those that we were done, unless the perfect castle-style wheel appealed.

you may also recall that my most beloved wheel is the pipy, made by philip poore in 1972:

the pipy was far and away the most common wheel that poore made, but there was...another wheel. a castle wheel. called the wendy.

when i was gift-shopping for upcoming birthdays the other day, i was on ebay, and one of my previous searches popped up. and i opened it, obviously, just to see, and because i like looking at spinning wheels and seeing what people are selling.

well, there were nine items on ebay that matched that search, one of which was a wendy wheel, made in 1975, not terribly expensive, and less than 50k from my house.

so you can probably guess what happened next.

...ok, actually what happened is that i waffled about it and made sad noises for a bit, and my wife spent an hour or so whispering do it, do it, and then the obvious happened.

so now for real we have our (probably) last wheel (for now)! and buddies, lemme tell you, she's absolutely majestic. she's so small that if you take her apart, i'm pretty sure she'd fit into a carry-on-sized suitcase. she's so small that if i, a normal-to-tall-sized human person stand next to her, the top of the drive wheel is under my knee.

she also has a delightfully unusual tension system! frame flyers were apparently (relatively) briefly popular in new zealand, and honestly, i kinda dig it?

the rod is actually in two pieces, and they're connected by the threaded ball. turn the ball in one direction, and the upper part of the rod moves slightly further out of the ball; turn it in the other direction, and the rod moves deeper into the ball. this changes the tilt of the flyer, moving it slightly closer to or further from the drive wheel, and thus adjusting the tension. [update: you can see a video of it in action in this post!]

the flyer's slightly cracked, so right now i'm using the single flyer across both wheels, but i'm talking to more experienced people to figure out how best to repair/replace it. other than that, though, she's in amazing condition—it's clear she was treasured, but equally clear that she wasn't used. (there was a giant clump of spiderweb in the orifice, and don't think that wasn't an unpleasant surprise.) but i think we're more than happy to use her enough to make up for the years of disuse.

oh, and in the picture looking down, see that little hole in the frame, just at the bottom of the image? it's so you can screw a block of wood onto the frame and convert her to scotch tension, if you'd like.

she came with her original paperwork, featuring information about how to prepare wool, spin, and knit it, which is also rather charming.

this concludes the most recent (and probably final) episode of 'slightly odd spinning wheels that are older than i am that i have bought for a song'. i know i've said it before, but if you have the chance to play with vintage wheels, please do give it a go. sometimes they're just so-so, but sometimes you find absolute treasures that were made by masters of the craft, and then—hypothetically—you own four of them that collectively have still cost you less than the price of buying one (1) ashford traditional.

#spinning#hand spinning#handspinning#spinning wheels#fiber arts#fibre arts#fibrecraft#i really cannot overstate how much i love the poore wheels#they're just so incredibly thoughtfully made#and well made#and absolutely beautiful#anyhow heart eyes emoji you know?#also i want to be clear that there's no shade at ashford here!#i've used them and they're nice wheels!#i don't love them but i don't love a lot of things#i don't love louëts either and i've owned one#it's just that ashfords are widely available and i know what they cost#because literally everywhere sells them#and i'm lazy and don't want to go look up what a kromski or whatever costs#smartest raccoon i know#also special shoutout to my wife for 100% enabling this purchase#like they'll also benefit since now we have more wheels#but i don't know that i would've done it without the urging#even though it's exactly what i've been dreaming of#so that was nice of them

31 notes

·

View notes

Text

So I wanted to talk a little bit about my headcanon's for Viktor's disabilities / medical aids with regards to how I write him.

So bone rods and screws aren't a new technology to Arcane; they're a very real devices used to correct the spines of people with scoliosis, spinal stenosis, and other vertebral injuries/disease. Sometimes, pins, rods, and screws are used in other medical applications, such as severe fractures, correcting bowed-legs, and more. For example: growing rods, which are used to lengthen the spine in children, and harrington rods which are used to correct spinal curvature. The pin and rod/screw system that Viktor displays, however, looks incredibly intense. Most spinal rods do not stick out of the skin, and most also don't have a bodice piece. I find it curious that there is only one strap, which makes it clear that it isn't really serving a purpose other than possibly holding the garment up due to strong tension between the screws/rods and the pins. The other thing I noticed is that there are the ports for the screws in the front as well, sort of directly lined up with here his sternum would be.

Whatever he has going on, my headcanon that there isn't enough material left in the spine itself to support all of the pins anymore ( which is why he has two that are disconnected from the brace ). Based on him saying he can feel his body deteorating, I believe he has some sort of advanced osteoporosis or other bone density issues - potentially something like rickets thats caused by diet deficiencies cause you know, undercity food scarcity. Because of bone deteoration, adjustments have had to be made to anchor the pins in his sternum as well. This is not helping with his illness, as it's putting additional pressure on his chest and lungs - but it's saving his spine from completely crumbling.

My Viktor has some routines in relation to his medical aids that will be shown in any longform threads. 1. He has a twice-daily routine where each port is cleaned, disinfected and then prepared for the brace, or in the case of the end of the day, prepared for bed time. Because the pin ports and screw system is essentially creating open wounds, they have to be cared for. This is an incredibly difficult task made easier by an extra set of hands. He has asked others to help him on days where his mobility is severely restricted, but he hates asking for help. 2. Once a month the screws are examined and tightened if necessary, in order to keep his spine straight. These adjustments are incredibly painful; worse if the adjustment causes a fracture due to bone porosity. It takes a few days for Viktor to recover after these adjustments, during which he can suffer from lethargy, agitation, insomnia, and other pain-related side effects. He often chooses to work through the pain, seeking a distraction, as he refuses to take pain medication which he believes clouds his thinking. 3. Every six months, his entire body is evaluated for continued need and use of the brace. He has not yet been cleared to have the corrective aids removed.

And all of this is in addition to whatever disease is ravaging his lungs. My poor boy is so sick...

2 notes

·

View notes

Text

Behind the scenes photo and rant under the fold

Okay, so, I was pretty excited to get this figure. But as great as it looks, it's been immensely disappointing.

His glasses were broken on arrival, which isn't a huge deal, I could always replace them. The real issue is in how the tentacles attach to the body.

The doc has these four cavities on his back, with nuts glued in them. And each tentacle has a threaded rod protruding from the base, to screw into the nut.

Now, even lining that up is a pain, the dude's wearing two jackets. So it's a case of feeding the base of the tentacle through these two layers of clothing, to get at the nut so you can screw it in and secure it. And you'd have to do that four times.

I was unable to do it more than once.

See, after getting the first tentacle screwed in, I tried bending it around so it'd be more out of the way while I struggled with the next tentacle. Apparently, bending it put too much stress on the nut, and pulled it loose.

I glued it back in, waited around a day for the glue to cure like you're supposed to, but the same thing happened.

Maybe if I use a different glue I'll have better results, but. I'm just hella stressed out over the whole ordeal. Truly, no man has suffered more at the hands of Otto Octavius than I.

#doctor octopus#otto octavius#doc ock#toy photography#action figure photography#marvel#artist on tumblr

25 notes

·

View notes

Video

youtube

📌Goodfix & Fixdex GROUP Factory2 Threaded Rod Manufacturing

We can producing

threaded rod / thread bar / stud bolt / Teflon Coated Threaded Rod and so on, yearly output 120,000 tons.

Certified factory of ETA ,ICC ,CE , UL, FM, ISO9001,CNAS AND CMA National High-tech EnterpriseStop by our factory to explore our high-quality products, and discuss how we can help you with one-stop solutions for your business.

Let's connect feel free to contact us https://www.fixdex.com/

Email: [email protected]

WhatsApp: +86 18002570677

#youtube#fixdex#goodfix#threaded rod#fixdex threaded rod#fixdex stud bolt#threaded stud bar#threaded stud bolts#threaded bar#standard threaded rod sizes#steel threaded rod tensile strength#zinc threaded rod#threaded stud screw#b7 threaded rod tensile strength

0 notes

Text

Jinnox Bolt is one of the leading Bolts, Nuts, Washers, Threaded Rod, Screw & Coated Fasteners Manufacturers in India. Our broad product line uses only the highest quality materials to ensure that it meets and exceeds industry requirements. We are very proud of our experienced team of experts who are committed to providing amazing customer service by ensuring that every product we manufacture is of the highest quality and delivered on time.

Bolts: https://jinnoxbolt.com/bolt-manufacturer-supplier-stockist-india/

Nuts: https://jinnoxbolt.com/nut-manufacturer-supplier-stockist-india/

Washers: https://jinnoxbolt.com/washers-manufacturer-supplier-stockist-india/

Threaded Rod:https://jinnoxbolt.com/threaded-rods-manufacturer-supplier-stockist-india/

0 notes

Text

Not sure if any of you have read Ocean's Echo, but this is fanfic for it! Surit is a cinnamon roll and I wouldn't have him any other way, but this is an 'assholes-slowly-learning-not-to-be-assholes' blog, so.

I wouldn't get attached to these guys in their current incarnation because this is likely to become original fiction and then all of this will become noncanon, but it might as well go here in the meantime.

“It will feel like a key in a lock,” the pilot in the instructional video had said. “Or like one of those telescoping rods - I don’t know, it could feel like something totally different to you. But you’ll feel it click. Might be difficult if the reader has strong walls - sometimes it’s hard for them to drop them, but they have drugs for if that happens.”

“All right,” the medical technician said, pushing the scanner wand on its articulated arm aside. She managed to look bored; how many of these did she oversee? “When you’re ready, sir.”

Davi moved in as if he was going to write the person in front of him, but - all of him? He tried to encompass too much of the mind at once, was pushed back by slippery walls and lost his grip.

“Could you try to drop your defences, please?” he asked, distantly, all of his attention focused internally. Anxiety and insecurity gnawed at him. He wasn’t doing it properly. It should be done by now. It hadn’t sounded like a difficult procedure in the instructional vid.

The reader - Davi’s reader, as soon as he managed to actually do the procedure - took a deep breath that hitched in the middle. He looked small, even now that the guard had left; shorter than Davi, hair cropped close, the featureless prison scrubs loose and faded in stark contrast to Davi’s smart uniform. The ID cuff on his left wrist had a wooden gender token on it, plainer and somehow even less like jewellery than Davi’s button.

“I don’t…. Do I have defences up?”

Davi gave him a suspicious look, but the reader looked honestly bewildered behind his neat little glasses. No formal training, huh.

“Yes, you do,” Davi told him. They wouldn’t have stopped a determined probe, but this wasn’t a normal probe and they made things just slippery enough that he couldn’t get purchase. “If you can relax and be open, this will be a lot easier.”

“I’ll - I’ll try.”

And he did, Davi could feel it, the walls softening and thinning and the mind turning its face up to him and -

It wasn’t a click, but he could see why you’d describe it like that. Like the threads of a screw-top jar engaging. Like one of those intricately carved puzzle boxes that needed to be moved in a very specific way before they opened up. More than anything, the sense that two things that were supposed to fit together in a whole had finally found the orientation in which they did. Davi reached out and pushed those pieces together firmly.

And suddenly there was a presence, filling the tiny interview room, warm and alive and close enough that Davi felt like he was crammed up against the walls moving with its breathing. Breathing with it.

The reader’s knees buckled. Davi was somehow there as soon as it happened, to catch the slight frame in his arms and stop him tumbling to the hard metal floor. He’d known that was going to happen because the body was his, in some weird way. Part of him.

The technician spun in her chair, pressed a few buttons. “Successful sync,” she said. “All vitals looking good.”

No, Davi wanted to say. Wait. They can’t all be good. If they’re good why does this feel…

What did it feel like?

He still felt like Davi. He was just Davi with… something else stapled into the middle of his senses. It was difficult to talk around it, difficult to think around it.

The reader’s fingers moved against the chest of his uniform shirt. Stiff coarse fabric, the line of piping hard underneath his thumb - wait, what?

The fingers closed up as if to grasp him, but then flattened to push him away. Sensation, emotion, something poured out of the unfamiliar presence in Davi’s head. He struggled to name it but it was… bad. Like fighting against a torrent of dark water.

You’re in control of this, he told himself. You’re the architect. This is under your control. Get a grip.

He set his mental shoulders against the deluge, tried to rise above it. He made himself push the reader’s body away from his - not you, that is not you, keep all of that to yourself - prop the reader back up, set him on his feet. The reader was looking around the room, blinking, looking as stunned as Davi probably was.

What have you done? What have you DONE?

The thought arrived in his head, not so much in words but more the impression, but still crystal clear and foreign. Blank horror.

“You should probably head back to your quarters and rest,” the technician told him. “It’ll take a while for you both to settle into it.” She retrieved something from one of the cupboards in the med-bay - a rectangular packet of cloth. She slapped a packet of medication tabs on top of it and held it out to Davi. “Standard issue equipment for Agent Thirty-two; you shouldn’t need these, but just in case. Come back here tomorrow, or sooner if there are any issues. Do you need help getting him to your quarters?”

Davi didn’t question why she was giving the pack of uniforms to him and not to the reader, swaying and wavering in the middle of the room. Even if the other man hadn’t been on the brink of falling over or throwing up, he was Davi’s responsibility now.

He would always be Davi’s responsibility.

Oh Guidance lights what have I done…

Davi shook off the thought, exerted what he hoped was firm but gentle pressure on the alien presence in his head until it receded a little. He stepped forward and took the packet.

“No, that will be fine,” he said. “Our quarters aren’t far, and we can walk without assistance. Thank you.”

The technician gave him an odd look as he tucked it under his arm.

“Need a tissue, sir?”

“What?” Davi put a hand up to his face. To his complete surprise, his eyes were streaming with tears. He hadn’t even noticed.

The reader - Agent Thirty-two - Saelin Cor - made another small noise from behind Davi, a pained inhale. He was lifting one hand up to his temple, fingers pushing through his hair, and Davi was suddenly convinced that it was supposed to be much longer than it was, that having it short and prickly was strange and unfamiliar still.

Davi hadn’t needed to see him to know any of that.

“I’m fine,” he said roughly. Panic fluttered at the edges of his mind - what have I done what have we done what is this - and if not all of it receded when he shoved it away, well, it would improve. Nobody was expecting them to be out there at the bridge tomorrow. There was time to figure this out.

He blotted one side of his face with the heel of his hand, and turned away. “We’re fine. Come on - Agent Thirty-two. Let’s go home.”

Continued here.

#whump writing#fanfiction#Ocean's Echo fanfic#not my world#my OCs#incidentally Ocean's Echo is good and you should read it#mind-link#telepathic whumpee#Oppressed telepath#involuntary telepathy#non-consensual mind-link#Saelin and Davi

5 notes

·

View notes

Text

The Benefits of Installing a Socket Screw Self-Tapping Screw Threaded Rod Bolt and Rod.

In the sector of production, production, and DIY tasks, the significance of choosing the right fasteners can not be overstated. Whether you are constructing a new shape, repairing gadget, or assembling fixtures, the integrity and reliability of your connections depend closely on the nice of the fasteners you use. Among the myriad options available, socket screws, self-tapping screws, threaded rods, bolt and screw, washers, and nuts stand out as flexible answers with a plethora of benefits. In this weblog publish, we're going to delve into the advantages of those important components and discover how they could elevate your projects to new heights.

Socket Screws: Strength and Precision

Socket screws, additionally called Allen screws or hex socket cap screws, are a popular preference for packages requiring excessive energy and precision. These screws characteristic a cylindrical head with a recessed hexagonal socket, making an allowance for steady tightening with an Allen wrench or hex key. The key benefit of socket screws lies of their ability to deliver notable torque transmission and resistance to loosening under vibration. Whether you are assembling equipment, securing components in electronics, or fastening structural factors, socket screws offer the reliability and stability needed for vital connections.

In industries where precision is paramount, consisting of aerospace and car manufacturing, socket screws play a essential position in making sure the integrity and performance of complicated systems. Their uniformity and consistency make them ideal for high-tolerance packages, in which even minor deviations may have enormous results. By the use of socket screws, engineers and developers can gain tight fits, limit play, and preserve most fulfilling alignment, thereby improving the overall best and durability of their products.

Self-Tapping Screws: Efficiency and Versatility

Self-tapping screws represent a revolutionary advancement in fastening generation, presenting unprecedented efficiency and flexibility in a huge range of applications. Unlike conventional screws that require pre-drilled pilot holes, self-tapping screws characteristic a unique cutting or tapping mechanism that lets in them to create their very own threads as they're driven into the cloth. This gets rid of the need for separate tapping operations, saving time, hard work, and resources.

Whether you are running with steel, wood, plastic, or composite materials, self-tapping screws excel in imparting secure and reliable fastening solutions. From roofing installations and carpentry tasks to car repairs and DIY endeavors, self-tapping screws empower customers to address numerous obligations comfortably and self assurance. Their potential to penetrate and grip numerous materials efficiently makes them indispensable in environments where traditional fasteners may struggle to deliver satisfactory results.

Threaded Rods, Bolts, and Nuts: Stability and Flexibility

Threaded rods, bolts, and nuts shape the spine of infinite systems and assemblies, supplying remarkable stability, flexibility, and electricity. Threaded rods, additionally known as studs, offer a non-stop fastening alternative for securing additives over long distances or bridging gaps between surfaces. Bolts and screw, however, characteristic a threaded shaft and a head designed for mating with nuts, permitting secure connections that can be without problems tightened or loosened as wanted.

Nuts and washers supplement threaded rods and bolts by using providing extra assist, distributing masses lightly, and preventing loosening due to vibration or thermal enlargement. Together, these components shape a strong and reliable fastening system that may withstand intense forces, harsh environments, and worrying operating conditions. Whether you are building a constructing, installing machinery, or repairing infrastructure, threaded rods, bolts, nuts, and washers offer the structural integrity and peace of mind necessary for a hit consequences.

Conclusion: Elevate Your Projects with Quality Fasteners

In end, the blessings of socket screws, self-tapping screws, threaded rods, bolts, washers, and nuts are undeniable. From their strength and precision to their efficiency and flexibility, those important additives play a important position in the achievement of production, production, and DIY tasks worldwide. By deciding on the proper fasteners for your unique desires, you could beautify the pleasant, durability, and overall performance of your creations, ensuring lengthy-lasting effects that stand the check of time.

When it involves sourcing fantastic stainless-steel fasteners and components, Anand Steel stands out as a depended on companion you could rely upon. As a main importer and exporter of chrome steel shims, strips, coils, foils, round bars, and distinctiveness nickel alloys, Anand Steel takes satisfaction in handing over excellence in every product they offer. With years of enjoy and expertise, they have got established themselves as a reliable and relied on supplier inside the industry.

Contact Anand Steel today to discover how their comprehensive range of merchandise and unwavering commitment to first-class and purchaser pride can elevate your tasks to new heights. Whether you want stainless steel solutions for construction, production, or any other industry, they have the knowledge and sources to satisfy your requirements with precision and professionalism. Experience the distinction with Anand Steel and unencumber the total capacity of your initiatives.

0 notes

Text

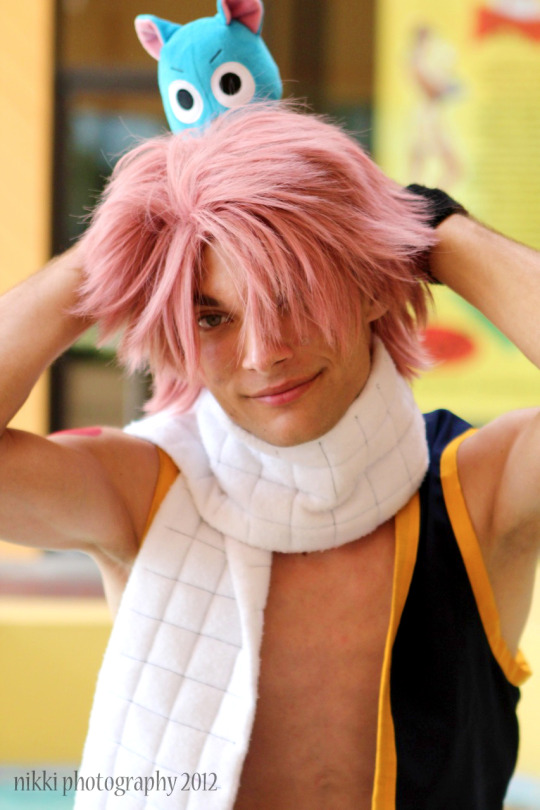

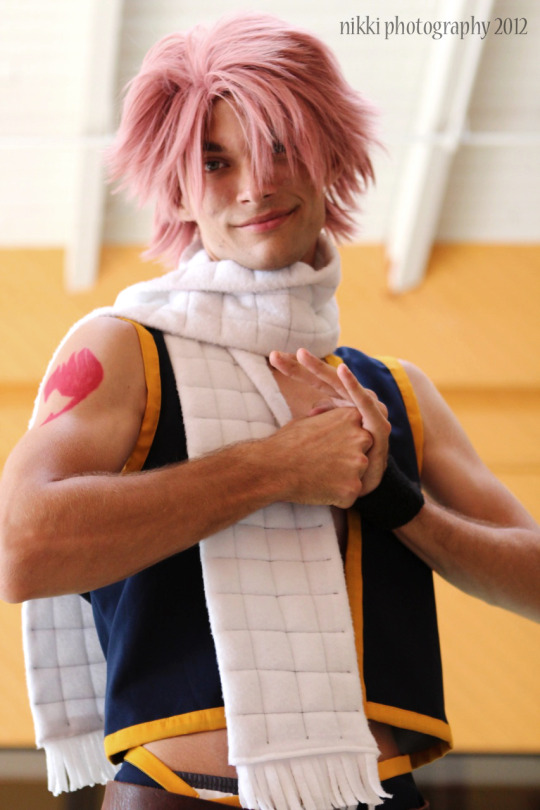

No. 17 - 2012

Character: Erza Scarlet (Armorless ver.) Series: Fairy Tail by Mashima Hiro

Cosplayer Credits: - Natsu : My brother - Gray : Jaiden - Lucy : Kirky

Photog Credits: - Axel - David Ho - Nikki Smith Photography

==========

This is genuinely one of my absolute favorite costumes, and one of the ones I'm still so proud of today!

Like Shiki, I decided to make this particular version of Erza's because I saw an opportunity to make something I'd always wanted to make: a hakama! Does she actually wear a hakama? Not really, but who cares?!

==========

My wig is from Epic Cosplay Wigs. The top is two parts. The first was made from white spandex and is essentially a tube top. I then cover it with drug-store gauze that sticks to itself once it's in place. The bottom, which you can't really see, is made from the same white spandex as the top. I made a pattern from a pair of tights I already had only it goes down to just before my knees.

The hakama is made from red denim-like cotton. I used Folkwear pattern 151, Hakama and Kataginu. I used appliqué (HeatnBond Lite) for the flames at the bottom; the fabrics were similar to the red. For my back board, I fused some spare red to a few pieces of 16th of an inch-thick piece of interfacing. It is washable this way but still stiff as a board and bendable like professional hakama.

I originally wanted to do the tattoo with Hollywood Ink Henna pens and a stencil, but when we got to the convention Friday, we saw they had temporary tattoos in all of the colors we needed and we figured that'd be easier and faster. Plus, most of us were wearing things the next day that would've shown the guildmark so we didn't want them to clash. I later bought actual temp tattoo pens from Stargazers.

I made Benizakura to go with this costume in 2017. It is made of 1/4 plywood for the core blade and hilt. The tsuba (guard) is made of 3/4 plywood that I sanded down to about 5/16 of an inch. I also sanded the hilt pieces from 1/4 to about 1/8 so the hilt came to 1/2 an inch. I used thin foam to finish the designs: the over-layer on the tsuba, the swirls on the hilt, and the pummel. Lastly, the tassel is made out of actual tassel, three wooden craft beads painted red, and screw in loop painted gold. The tassel was beaded and then, after strung through the loop, glue into the top bead.

And speaking of late add-ons... I also didn't have the time to make her earrings but I did eventually, so look out for them in some of these shots. They are made out of a half-inch square acrylic rod that I sanded down using a grinder wheel. A friend carefully drilled a small hole for the wire that I twisted, covered with a bead, and attached to a clamp earring, since I don't have pierced ears. Everything was spray painted to match.

Now my brother's costume was also a lot of fun to make. Aside from his height, he really does have a lot in common with Natsu, so it was a lot of fun to be these two. We got the wig from Fantasy Sheep on eBay; came pre-styled.

The scarf was made out of white fleece. Essentially, I made a pillowcase-like piece, inserted a thin layer of polyfoam, sewed the fringes between the "pillowcase"'s sides as it was shut, and sewed the different sections with black thread. I'm very proud of it because it bulges up and sections off like the references.

I used dark navy blue broadcloth for the front fabric and I insisted it should be reversable as per the Tenroujima Arc, I used grey broadcloth as the lining fabric. The trim is gold poly-cotton. I modified a simple shirt pattern I already had as the vest was not very complicated. We actually bought both the belt buckle and interchangeable belt from PiercingPros on Amazon.

Same fabric and idea as the vest, for the "skirt." I measured his waist, marking the middle, and then halving that measurement to add to it to get the bottom measurement, lining up the middles. (In case that was confusing, here's a formula: W = waist measurement; B = Bottom measurement; W + (W/2) = B) It connects at the top, under the belt with hook-n-eye clasps.

I modified the pants pattern from Kouma. I used white broadcloth held up with an elastic waistband. The calf ties are extra navy broadcloth fashioned like trim after bunching the ends of the pants and have hook and eye clasps on the inside seam. The knots are made separately and then sewn into place They were actually made by my friend Kirky.

==========

Erza: Cost: $60 Time: 16 hrs

Natsu: Cost: $60 Time: 10 hrs

==========

This costume has won the following award: - Best Anime Group @ Tate's NOT at ComicCon in 2012

#erza scarlet cosplay#fairy tail cosplay#anime cosplay#handmade cosplay#cosplay with a prop#natsu dragneel cosplay#for my brother#award winning cosplay

3 notes

·

View notes